Nathan Friend

Remote Software Engineer at Stripe and cellist based out of Ontario. Previously at GitLab. Fascinated with building usable, delightful software.

Useful things I've 3D printed

November 25, 2024 | 10 minutes to read

3D printers are ridiculously cool. There’s something about seeing a digital object slowly manifest in the real world that is pure magic.

But they’re also useful. Being able to custom manufacture replacement parts can save otherwise perfectly-working equipment from the landfill.

I’ve written before about some of the things I’ve 3D printed, including my Zoom light and my weird keyboard; here are some other useful things I’ve printed:

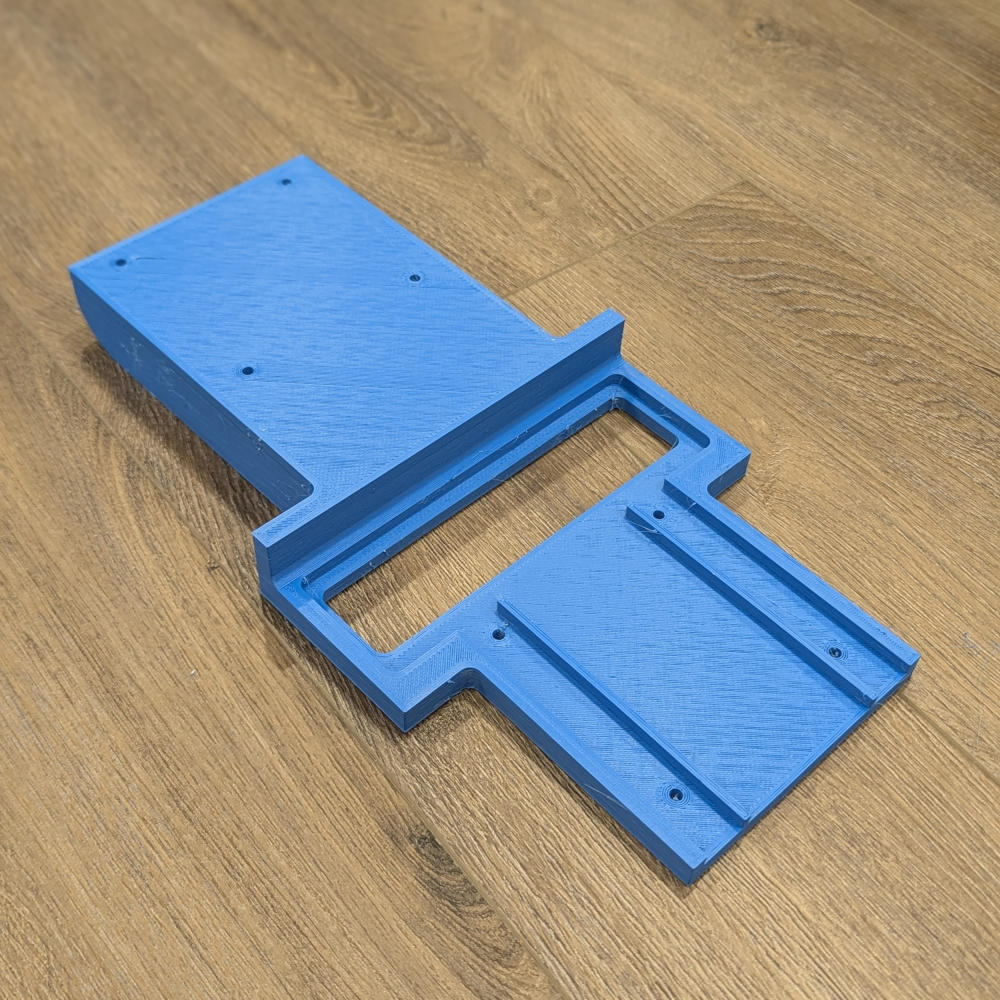

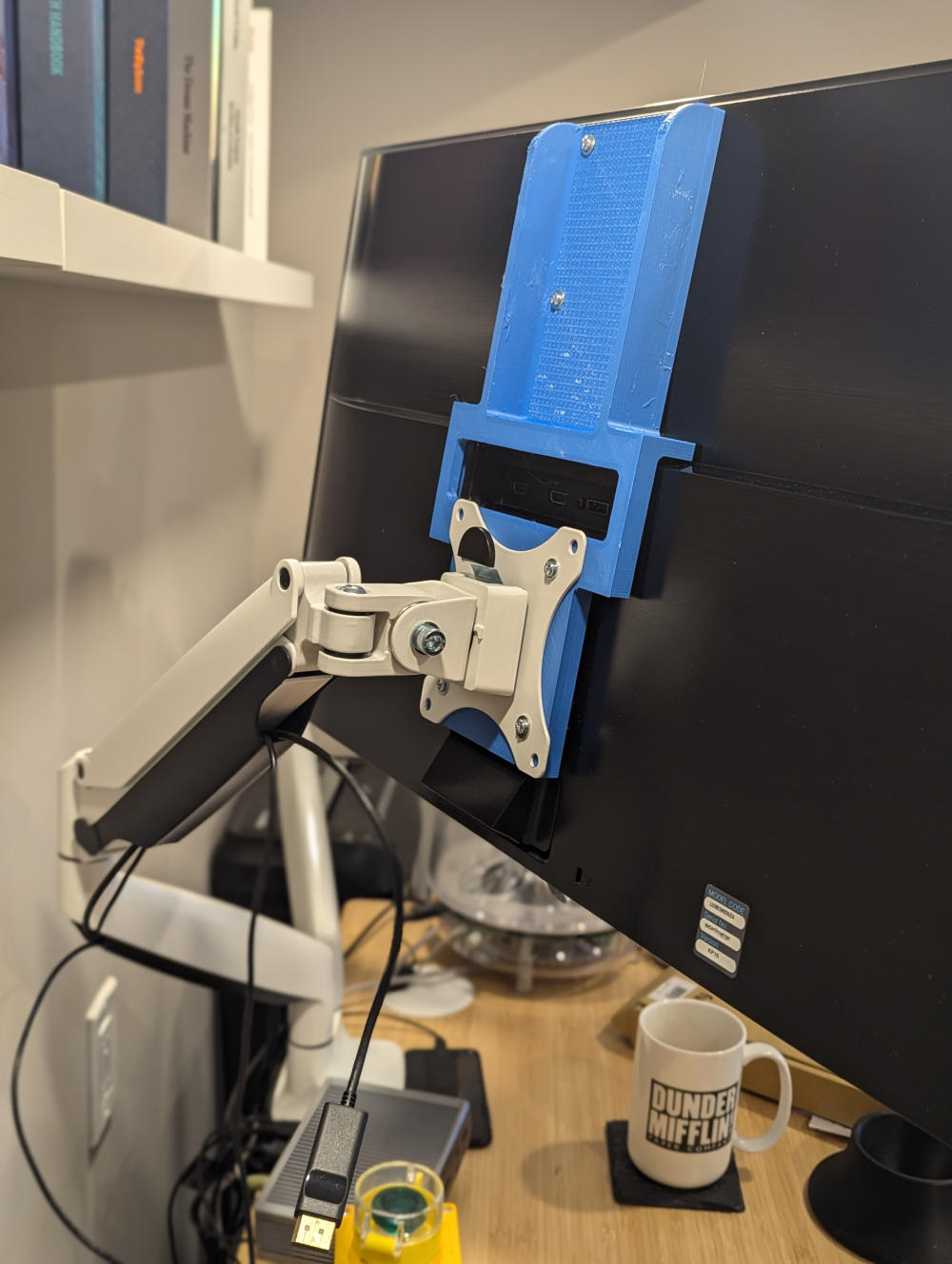

Monitor arm adapter

My main monitor - a Samsung U28E590D - has a terrible design flaw. Its VESA mount is at the very top of the monitor! This means that when connected to my monitor arms, it sits much too low, even with the arm at its maximum height.

While searching for solutions, I ran across this adapter, which effectively moves the VESA connection near the bottom of the monitor. Sadly, I couldn’t find a way to purchase it in Canada. So I decided to design and print my own!

I originally printed the adapter in PETG, as PETG is strong and flexible and usually a better choice for functional prints. However, it was a little too flexible - it caused my monitor to bounce around in a sickening way whenever I bumped my desk. I printed another in PLA (unfortunately the only color I had in enough quantity was a bright blue), which is much stiffer and has mostly eliminated the wobble.

Thingiverse link: https://www.thingiverse.com/thing:6845708

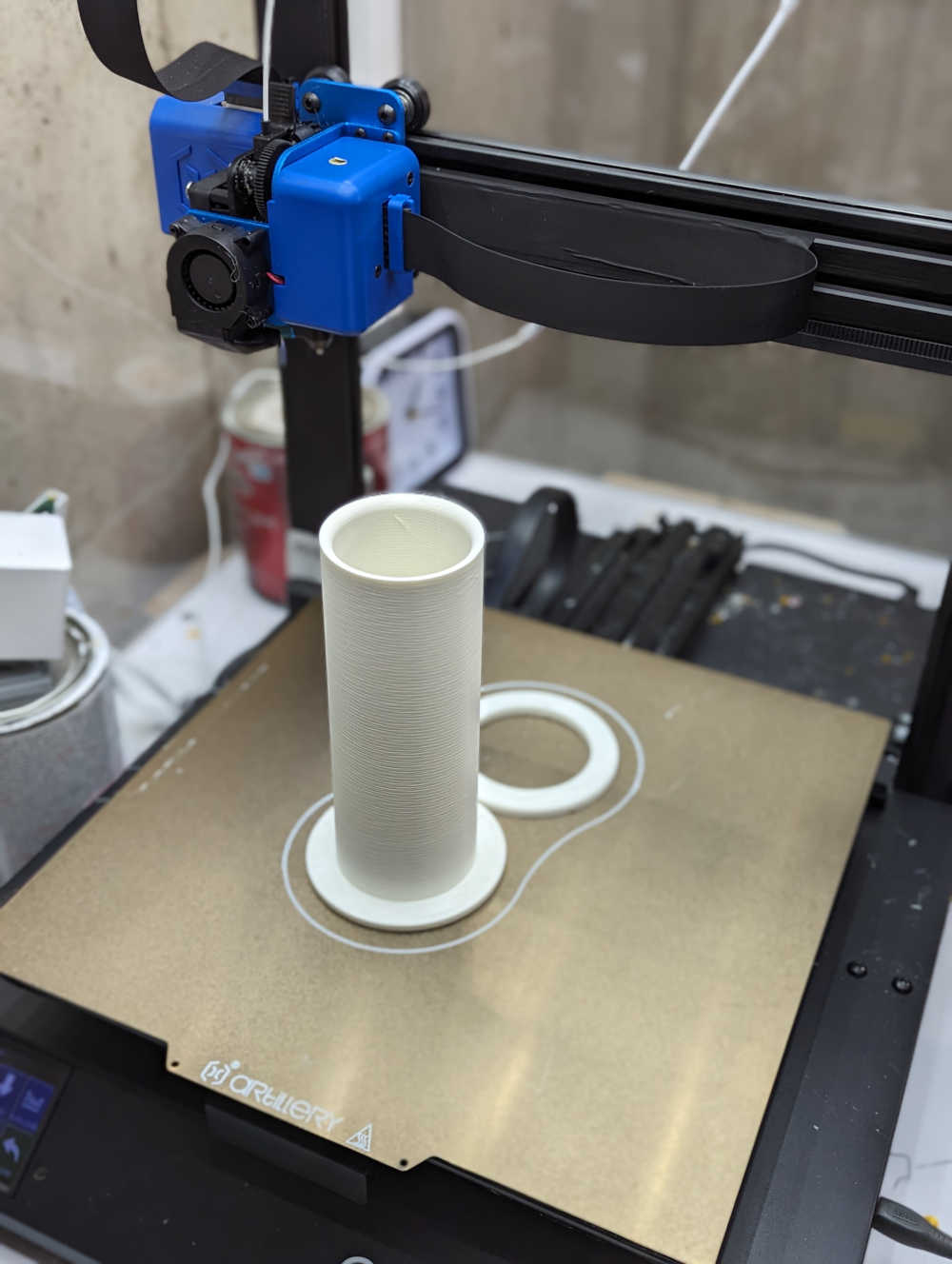

SodaStream bottle stabilizer

I drink way too much carbonated water, usually straight from the SodaStream bottle. The bottles look cool, but their tiny bases resulted in many a messy spill.

I modeled a base using the exact curvature of the bottle’s bottom, resulting in a nearly untippable receptacle.

As silly as it sounds, this simple print might be the most-used 3D printed object in my house.

Thingiverse link: https://www.thingiverse.com/thing:5422282

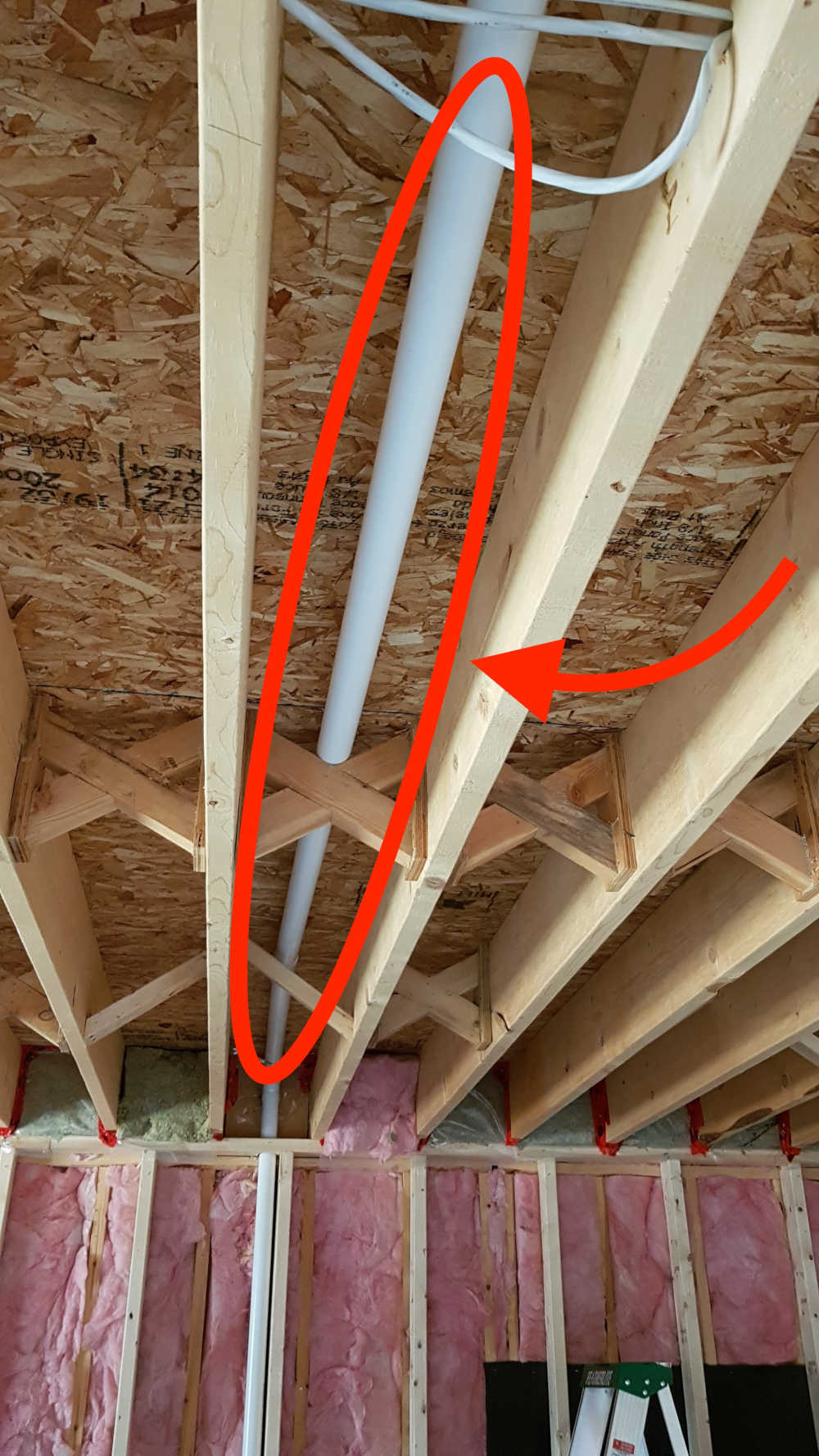

Conduit cover

When we finished our basement, I installed a conduit in the wall with the idea that maybe someday I’d set up a ceiling-mounted projector and need a clean way to route the cables.

This left some unseemly holes in our wall once the drywall was in place:

I modeled and printed covers for each end of the conduit:

They weren’t the cleanest prints, but it’s a huge improvement over the previous look!

Thingiverse link: https://www.thingiverse.com/thing:6847090

Dryer lint filter handle

One of my earliest functional prints was a new lint filter handle for my in-laws’ ancient dryer. The original handle had snapped off years ago and they had been using pliers to pull it out since then!

Thingiverse link: https://www.thingiverse.com/thing:6847164

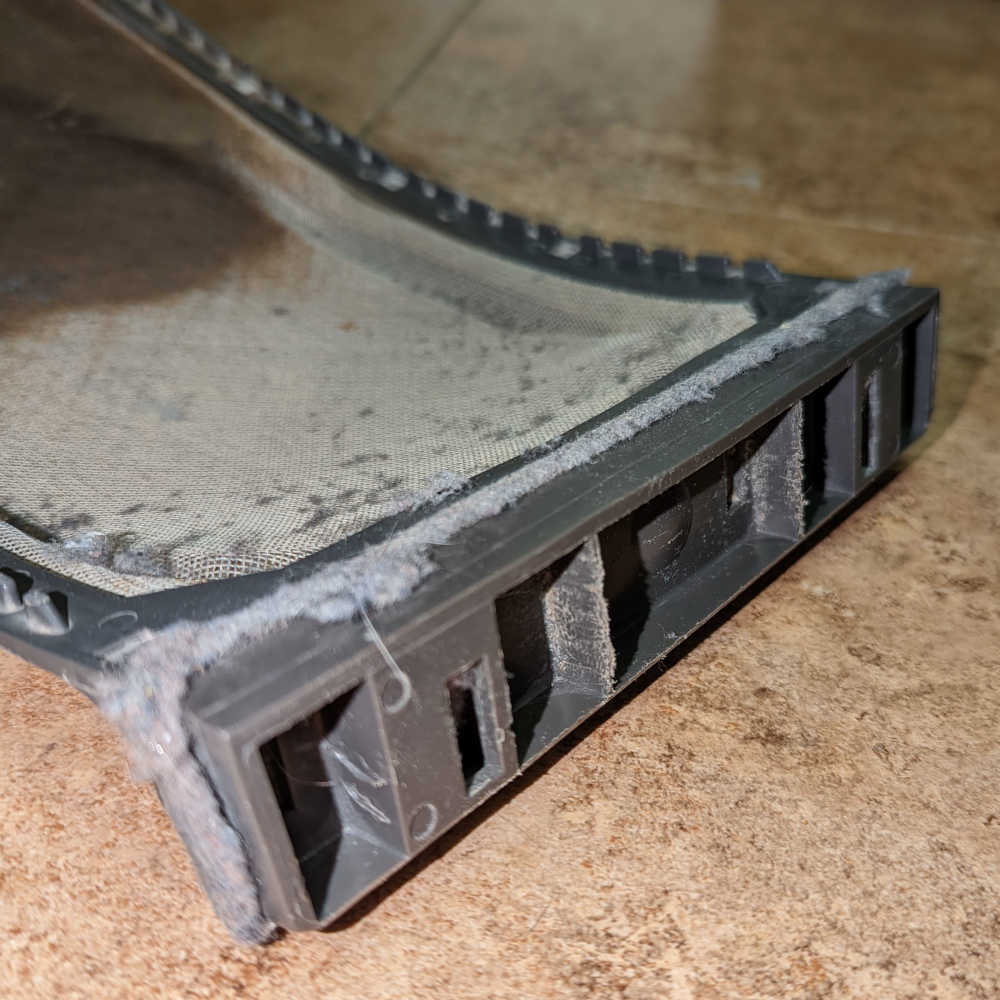

Dryer lint trap seal

We had our laundry room drywalled, and as part of this work, the contractor installed this terrible in-wall lint trap. Why is it so terrible? It has no latch, so every time the dryer starts, the filter pushes out of the wall, filling the room (and the entire house) with dryer lint dust!

I tried gluing some magnets to both the wall and the filter, hoping this would keep it in place, but the magnets were too finicky and didn’t hold it flush against the wall. In the end, we just taped it to the wall, which only kind of worked.

After replacing the tape for the nth time, I resigned myself to a more long-term solution. I designed a mount which I printed in PETG and attached to the wall around the existing filter.

I printed a cover that press-fit over this mount in TPU, a flexible, almost rubbery plastic:

Thingiverse link: https://www.thingiverse.com/thing:6876991

TV wall mount conduit

When I wall-mounted our TV, I wanted a clean look without any visible cables. This involved cutting two holes through the wall behind the TV so that the cables could be run into the storage room behind the wall and then back to the cabinet underneath the TV:

To make this tidier, I printed two conduits that exactly matched the depth of the wall.

This made running the cables much easier and cleaner.

The end result is a floating TV that seemingly requires no power source or video cables!

(You might also notice the LED backlighting; this is an ambient lighting setup I installed that is powered by Hyperion, which could be the subject of a blog post of its own!)

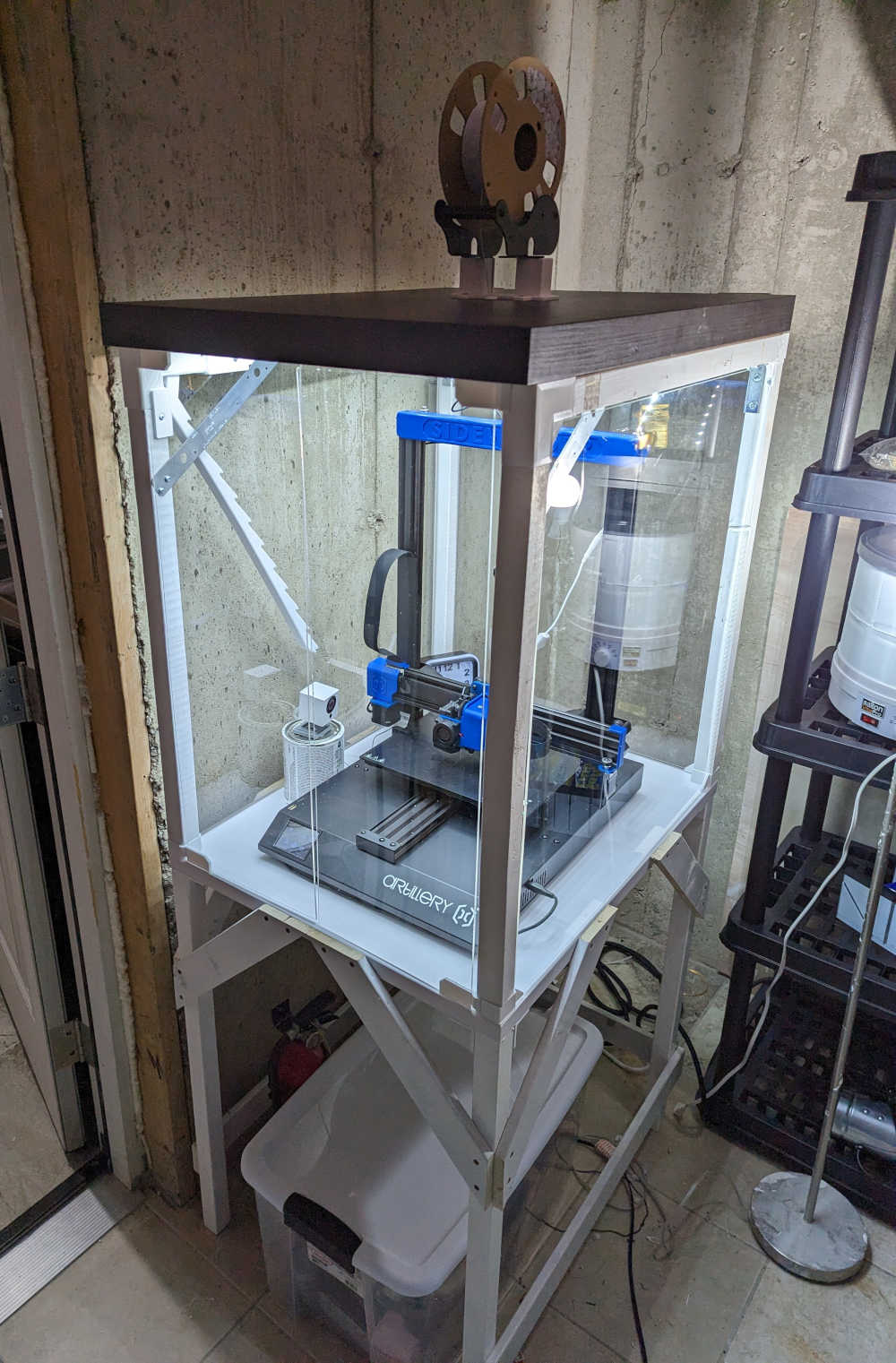

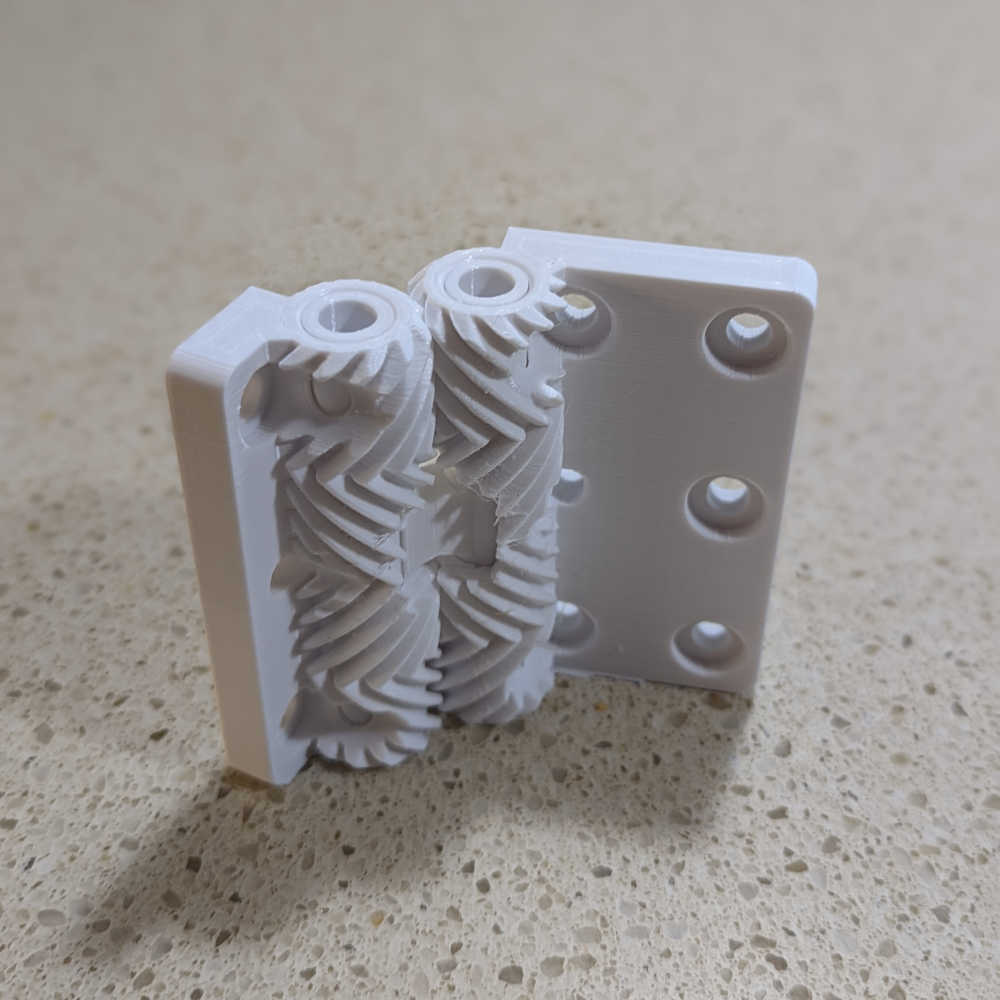

3D printer enclosure

I built my own 3D printer enclosure to help stabilize the ambient temperature during prints (especially for plastic prone to warping, like PETG).

While the structure itself was mainly built from wood scraps, most of the joints, hinges, and other interesting pieces were 3D printed in white PETG.

Printables link for the hinge: https://www.printables.com/model/120766-print-in-place-geared-hinge

Laptop stand

A friend needed a laptop stand, so I printed him one!

Unlike most of these other models, I didn’t design this one myself; I found it here.

Thingiverse link: https://www.thingiverse.com/thing:3708825

Yeti adapter

Another friend had a Yeti can insulator that was designed for 16 oz cans and was therefore too long for standard 12 oz cans. I printed a spacer so that the insulator could work with either.

Clamping mitre box

I wanted a large mitre box to help me make straight wood cuts:

While it was fun to model and print, it was ultimately a failure as it broke within the first five minutes of usage.

Thingiverse link: https://www.thingiverse.com/thing:5380012

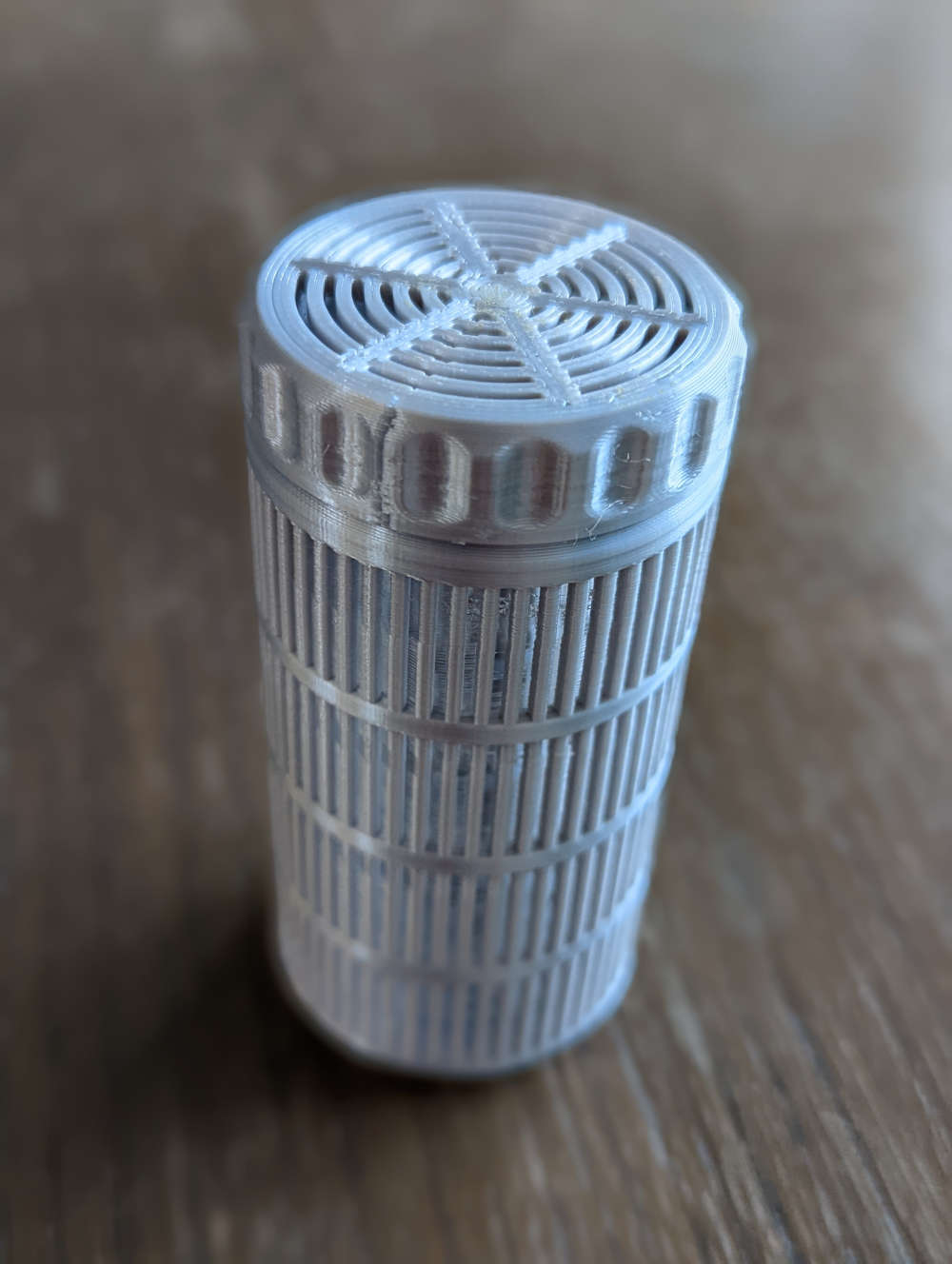

Desiccant containers

3D printer filament needs to be kept dry; it naturally absorbs humidity from the air which can negatively impact print quality. I printed some desiccant containers that I keep alongside my filament spools in a sealed plastic tub.

Although, to be honest, I don’t think they are doing much good; the desiccant beads are supposed to be recharged in the oven or microwave every few months, and ain’t nobody got time for that.

Instead, I now dry individual filament spools using a food dehydrator like this.

Poster frame

I got this funky poster as part of a swag package from Stripe. I modeled some matching low-poly poster holders that clamp together with magnets to display in my home office.

Thingiverse link: https://www.thingiverse.com/thing:6848192

Smoke alarm cover

Our smoke and carbon monoxide detectors expired, so I replaced the individual units with a single, combined detector. This left an empty hole in the ceiling of each room, so I printed a simple cover that snapped into the existing bracket.

Thingiverse link: https://www.thingiverse.com/thing:6449765

Cabinet legs

We bought an IKEA BESTÅ TV cabinet, but discovered the doors got caught in our shag area rug. I printed some simple legs to elevate the cabinet just enough to allow the doors to operate unobstructed.

Thingiverse link: https://www.thingiverse.com/thing:6848214

Coaster

While not strictly functional, I printed some Link-themed drink coasters for myself and my team at Stripe.

Google WiFi wall mount

I designed a wall mount for a Google WiFi access point. The fit wasn’t quite right due to my not noticing the top of the puck is slightly smaller than the bottom, but a well-placed wad of sticky tack did the trick.

Thingiverse link: https://www.thingiverse.com/thing:6903032

And more to come!

I plan on treating this post as an evergreen log of the functional things I’ve printed. Be sure to revisit!

Other posts you may enjoy:

GitLab Pages with multiple domains

October 14, 2024 | 3 minutes to read

Zoom light

May 31, 2024 | 6 minutes to read

I built a weird keyboard

June 26, 2023 | 13 minutes to read

Wordle Bot

January 25, 2022 | 7 minutes to read

Herding Gits

August 26, 2021 | 2 minutes to read